I. Principles and Advantages of Femtosecond Laser Cold Processing Technology

Femtosecond laser cold processing technology utilizes ultrashort pulses (pulse widths < 10⁻¹⁵ seconds) to achieve "cold processing" of materials, that is, a processing process without a heat-affected zone (HAZ). Compared to traditional mechanical drilling and electrical discharge machining (EDM), femtosecond laser processing offers the following significant advantages:

1.No Heat-Affected Zone: The ultrashort pulses of femtosecond lasers enable the release of energy in an extremely short time, preventing heat accumulation and conduction, thereby achieving a heat-free processing process. This helps maintain the integrity of the material's microstructure, reducing thermal damage and the formation of recast layers.

2.High-Precision Processing: Femtosecond laser processing can achieve sub-micron-level processing precision, with hole diameter deviations controlled within ±1μm, meeting the stringent requirements for Showerhead microhole sizes in advanced processes.

3.Wide Applicability: Femtosecond laser processing is suitable not only for metallic materials but also for high-hardness non-metallic materials such as CVD-SiC and aluminum nitride, providing more material options for Showerhead manufacturing.

4.High Processing Efficiency: Through multi-axis dynamic focusing systems and high-repetition-rate femtosecond pulses, femtosecond laser processing enables high-speed drilling, significantly improving processing efficiency.

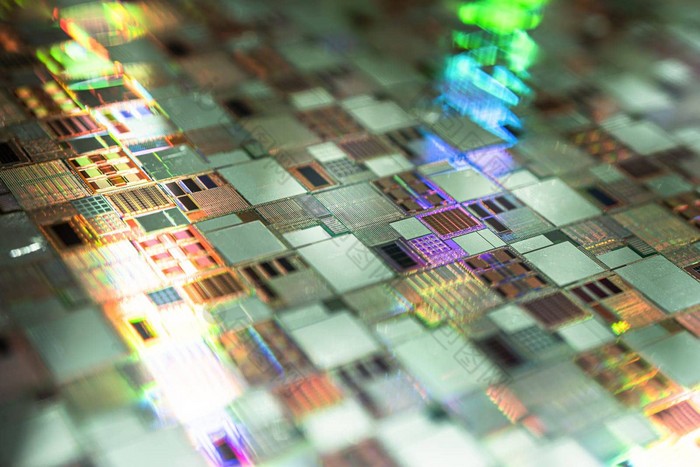

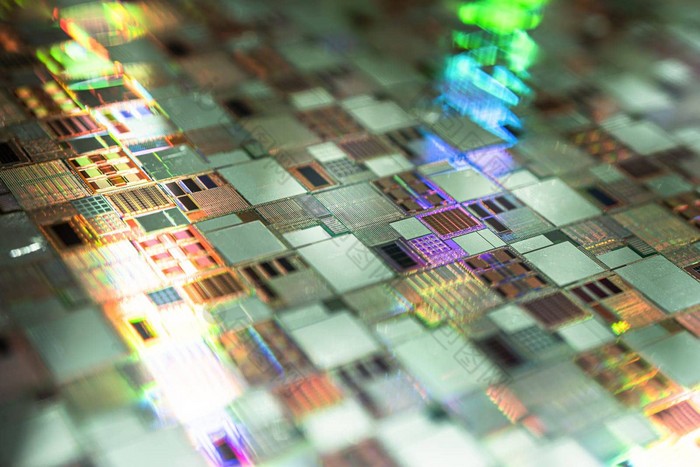

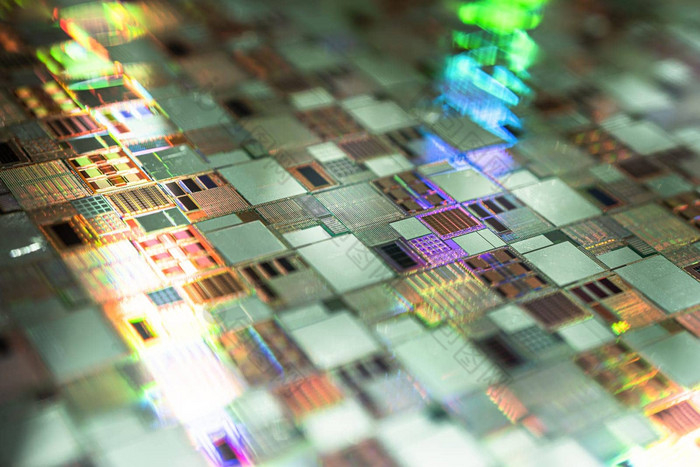

II. Application Cases of Femtosecond Lasers in Showerhead Manufacturing

Take Anhui Boxin Micro Semiconductor Technology Co., Ltd. as an example. The company has adopted femtosecond laser cold processing technology in Showerhead manufacturing. Using a multi-axis dynamic focusing system and high-repetition-rate femtosecond pulses, it has achieved the fabrication of Showerheads with micro-sized holes (20-30μm in diameter) and high hole densities (150,000 holes per piece) on molybdenum-based materials. Meanwhile, femtosecond laser processing maintains extremely high hole wall smoothness (Ra < 0.3μm), helping to reduce particle contamination caused by plasma erosion and thereby enhancing semiconductor manufacturing yields.

In addition, femtosecond laser processing technology is also applied to the aperture correction and surface functionalization treatment of Showerheads. By combining femtosecond laser processing with atomic layer deposition (ALD) technology, nanoscale correction of Showerhead apertures is achieved, with a correction precision of ±0.05μm. Meanwhile, by depositing coatings such as fluorides or hydrophobic polymers via ALD, the surface energy of the Showerhead is reduced, minimizing particle shedding and further improving semiconductor manufacturing yields and reliability.

III. Challenges and Future Prospects of Femtosecond Laser Cold Processing Technology

Despite its significant potential for application in Showerhead manufacturing, femtosecond laser cold processing technology still faces some challenges. Firstly, the unit price of femtosecond laser equipment is exorbitant (exceeding $5 million), with processing costs several times those of traditional technologies, limiting its widespread application in mid-to-low-end processes. Secondly, the daily production capacity of a single femtosecond laser processing unit is limited (5-10 12-inch Showerheads per day), making it difficult to meet the demands of large-scale production.

However, with continuous technological advancements and gradual cost reductions, femtosecond laser cold processing technology is expected to play a more significant role in Showerhead manufacturing. In the future, through measures such as optimizing laser parameters, improving processing efficiency, and reducing equipment costs, femtosecond laser processing technology has the potential to become one of the mainstream technologies for Showerhead manufacturing. Meanwhile, as semiconductor manufacturing technologies continue to evolve, the performance requirements for Showerheads are also constantly increasing. Femtosecond laser processing technology will be combined with other advanced technologies to jointly drive Showerhead manufacturing towards higher precision, lower costs, and greater intelligence.

AMTD provides high-precision Showerhead (spray head/gas uniformity plate/gas distribution plate) services for core components. Its products mainly include Shower heads, Face plates, Blocker Plates, Top Plates, Shields, Liners, pumping rings, Edge Rings, and other core semiconductor equipment components. These products are widely used in semiconductor and display panel fields, exhibiting excellent performance and high market recognition.

Content Source: Compiled from "Frontier Cases of Femtosecond Laser Micronano Processing: The 10,000-Hole Array of Semiconductor Equipment Spray Heads (Gas Uniformity Plates)", "Analysis of Showerhead (Spray Head/Gas Distribution Plate) Production and Processing Technologies", and relevant industry reports.

上一篇:Showerhead Machining: Limitations and Challenges of Traditional Processing Technologies

下一篇:In-depth Analysis of Material Selection and Performance Requirements for Showerhead Machining