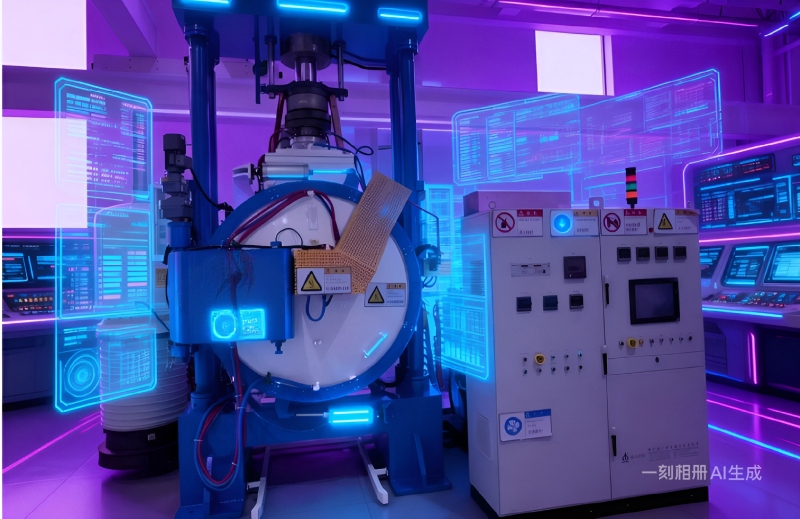

In metal-organic chemical vapor deposition (MOCVD) equipment, the Showerhead component serves as a crucial part for gas distribution, and its manufacturing quality directly impacts the uniformity of the deposited layer and device performance. In recent years, diffusion bonding technology has been widely applied in Showerhead manufacturing due to its unique advantages. This article will provide a detailed introduction to the practices and advantages of diffusion bonding technology in Showerhead manufacturing.

Traditional Challenges in Showerhead Manufacturing

Traditional Showerhead manufacturing often employs brazing technology. However, defects such as solder residue, overflow, solder flow, and solder shortage during the brazing process severely affect the cleanliness and welding strength of the Showerhead. Additionally, the potential introduction of contaminating elements during the brazing process poses a hidden threat to the performance of semiconductor devices.

Practices of Diffusion Bonding Technology

To address the shortcomings of traditional brazing technology, diffusion bonding technology has emerged as an ideal choice for Showerhead manufacturing due to its advantages of no solder contamination, high joint strength, and broad material compatibility. In practical applications, diffusion bonding technology enables the mutual diffusion of materials at the atomic level through high temperature and pressure, forming a metallurgical bond. During this process, no solder is used, effectively avoiding issues of solder residue and contamination.

Specifically, in the manufacturing of Showerheads, diffusion bonding technology not only facilitates multi-cavity designs but also significantly enhances welding strength and cleanliness. For example, in multi-channel Showerhead heater products used in MOCVD equipment, diffusion bonding technology ensures clean welds without overflow, greatly improving product reliability and service life.

Advantages of Diffusion Bonding Technology

1. Enhanced Welding Strength: The joint strength of diffusion bonding is close to that of the base materials, significantly higher than that of traditional brazing technology. This advantage is particularly crucial for Showerhead components that need to withstand high temperatures and pressures.

2. Guaranteed Cleanliness: Since no solder is used, diffusion bonding poses no contamination risk during the process, effectively ensuring the cleanliness of the Showerhead and meeting the high-purity requirements of semiconductor manufacturing.

3. Expanded Material Selection Range: Diffusion bonding technology exhibits broad material compatibility, enabling the welding of dissimilar metals and metal-ceramic materials, providing more possibilities for Showerhead design.

AMTD provides high-precision Showerhead services for core components, with products mainly including Shower heads, Face plates, Blocker Plates, Top Plates, Shields, Liners, pumping rings, Edge Rings, and other core semiconductor equipment parts. These products are widely applied in the semiconductor and display panel industries, demonstrating excellent performance and high market recognition.

Conclusion

Diffusion bonding technology, with its advantages of enhancing welding strength, guaranteeing cleanliness, and expanding material selection range, exhibits immense application potential in Showerhead manufacturing. As semiconductor technology continues to advance, diffusion bonding technology is expected to play an even more significant role in this field, driving continuous improvements in the performance and reliability of MOCVD equipment.