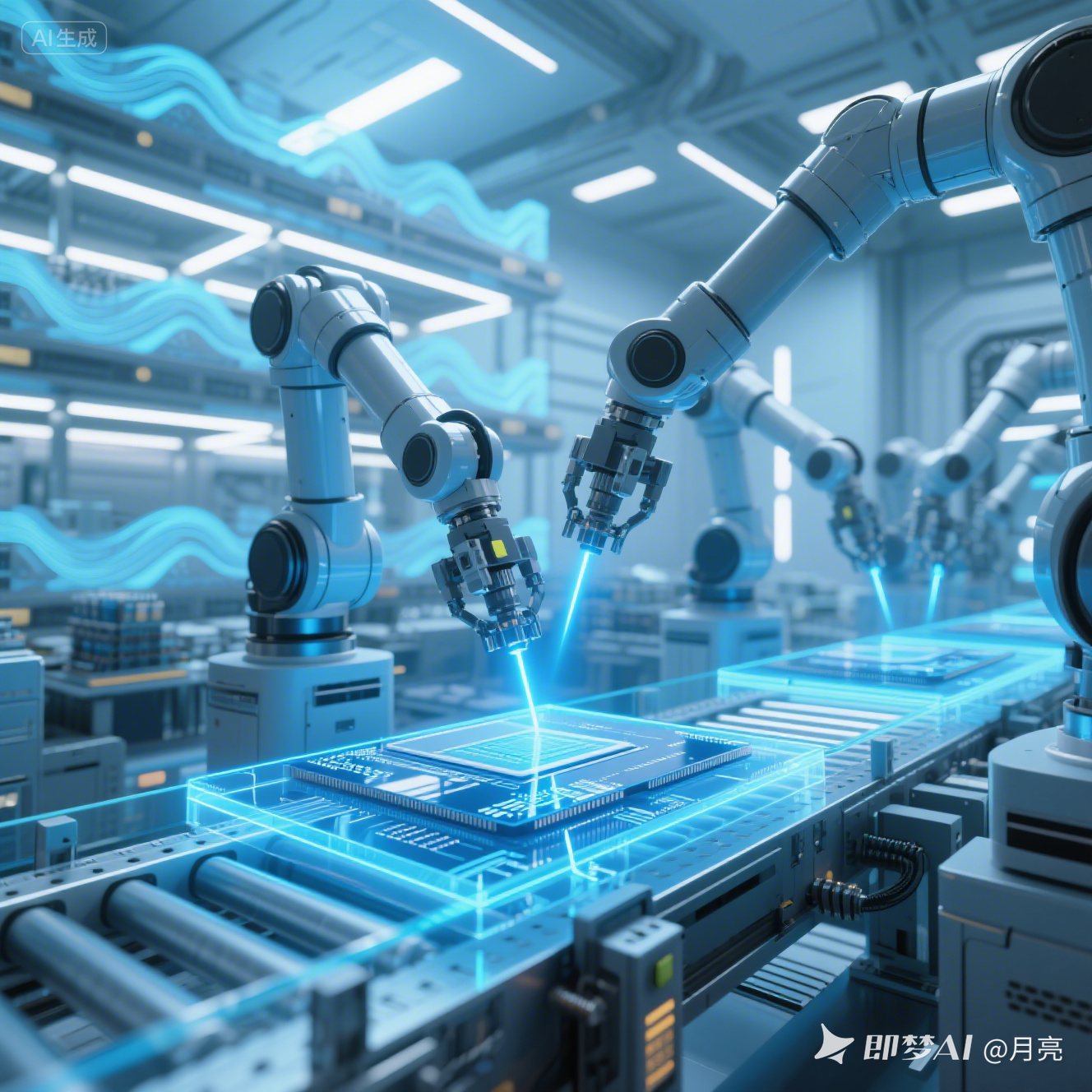

As semiconductor manufacturing advances towards more advanced processes, precision machining technology is emerging as the "future engine" driving industry innovation. From breakthroughs in material science to process optimization, and from equipment upgrades to the application of intelligent systems, precision machining technology will continuously empower semiconductor manufacturing, providing crucial support for global industrial upgrading.

Technological Trend: Interdisciplinary Integration

In the future, precision machining technology will deeply integrate with fields such as material science, artificial intelligence (AI), and intelligent manufacturing. For example, AI simulation optimization technology can predict gas flow channel design parameters through machine learning models, shortening the research and development cycle by over 30%. Meanwhile, spatial Atomic Layer Deposition (ALD) technology enhances deposition rates by parallel injection of multiple precursors, reducing the cost of ALD coatings by 60%.

Industry Outlook: A New Innovation and Development Landscape Led by AMTD

AMTD has made remarkable breakthroughs in the field of semiconductor precision machining, injecting new vitality into industry development. In terms of independent equipment R&D, AMTD has successfully overcome multiple technical challenges and achieved autonomous production of high-precision machining equipment. Its self-developed femtosecond laser equipment has reached international advanced levels in terms of machining accuracy and stability, meeting the stringent requirements for microhole machining in semiconductor manufacturing under advanced processes and providing reliable equipment support for domestic semiconductor enterprises.

In terms of process innovation, AMTD actively explores the integration of new technologies and applies advanced composite machining processes to semiconductor manufacturing. By combining femtosecond laser machining with processes such as Atomic Layer Deposition (ALD), it achieves precise modification and optimization of the surface and internal structures of semiconductor materials, significantly enhancing product performance and quality. This innovative process not only improves production efficiency but also reduces production costs, effectively driving the optimization and upgrading of the industrial chain.

Thanks to these breakthroughs, AMTD has led to a significant increase in the localization rate of the domestic semiconductor precision machining industrial chain. Under its exemplary leadership, more domestic enterprises have increased their R&D investments and actively participated in the innovation and competition of semiconductor precision machining technologies. As a result, the localization rate of the industrial chain has rapidly increased from 15% to 45%, effectively reducing the domestic semiconductor industry's dependence on foreign technologies and equipment.

At the same time, AMTD is also actively integrating into the global semiconductor industry ecosystem. On one hand, it engages in technical exchanges and cooperation with internationally renowned enterprises, introducing and absorbing advanced foreign technologies and management experiences to continuously enhance its technological capabilities and international competitiveness. On the other hand, it actively participates in the formulation of international standards, promoting the globalization of China's semiconductor precision machining technology and contributing to the construction of an open and innovative global semiconductor industry ecosystem. Driven by AMTD, precision machining technology will also become one of the core driving forces of the global semiconductor industry ecosystem.

Content Source: Semiconductor Manufacturing Technology Roadmap, Research Report on the Precision Machining Industry