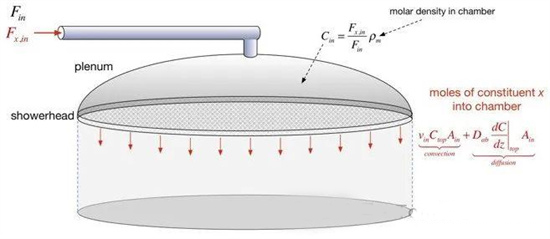

I. What is a Showerhead?

As shown in the figure above, a Showerhead, which can also be translated as a gas distribution plate or uniform gas distribution plate, is typically positioned closely against the upper part of the reaction zone and serves as the gas inlet. It uniformly injects reaction gases into the chamber through the tiny holes on its surface. Of course, it doesn't merely function for gas distribution; some well-designed Showerheads can also serve as part of an electrode.

II. What is the function of a Showerhead?

The surface of a Showerhead is densely covered with tiny holes. When reaction gases flow in, they are evenly divided into multiple portions and transmitted above the wafer at a consistent flow rate, ensuring that the reaction gases uniformly cover the entire wafer surface to produce a more uniform coating. When the Showerhead serves as part of an electrode, a radio-frequency power supply generates a uniform electric field on its surface, enabling the formation of a uniform plasma.

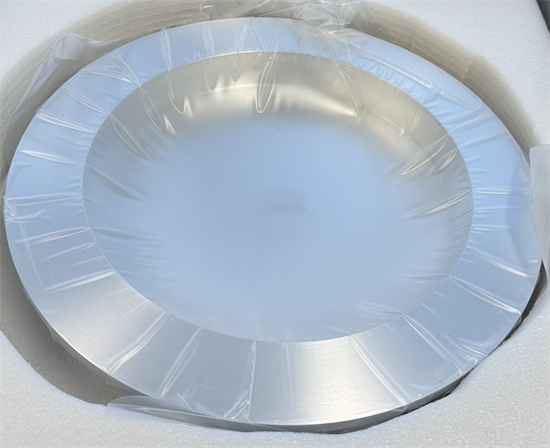

III. What metals are commonly used to make Showerheads?

Aluminum is the most commonly used metal due to its high thermal conductivity and corrosion resistance. Quartz or ceramics can also be used to manufacture Showerheads.

AMTD provides high-precision Showerhead services for core components. Its products mainly include Showerhead, Face plate, Blocker Plate, Top Plate, Shield, Liner, pumping ring, Edge Ring, and other core components for semiconductor equipment. These products are widely applied in fields such as semiconductors and display panels, boasting excellent performance and high market recognition.

Information Source: Publicly available data