The Shower Head (gas distributor in the form of a shower head) is usually positioned closely above the reaction zone and serves as the gas inlet, uniformly injecting reactive gases into the chamber through small holes on its surface. Its main functions are reflected in the following aspects:

Principle of operation: The design structure of the Shower Head enables it to evenly disperse and spray reactive gases onto the wafer surface. It typically features multiple tiny gas holes that are meticulously arranged and designed to achieve uniform distribution of the gases entering the reaction chamber over a larger area.

Importance: Uniform gas distribution is crucial during the etching process.

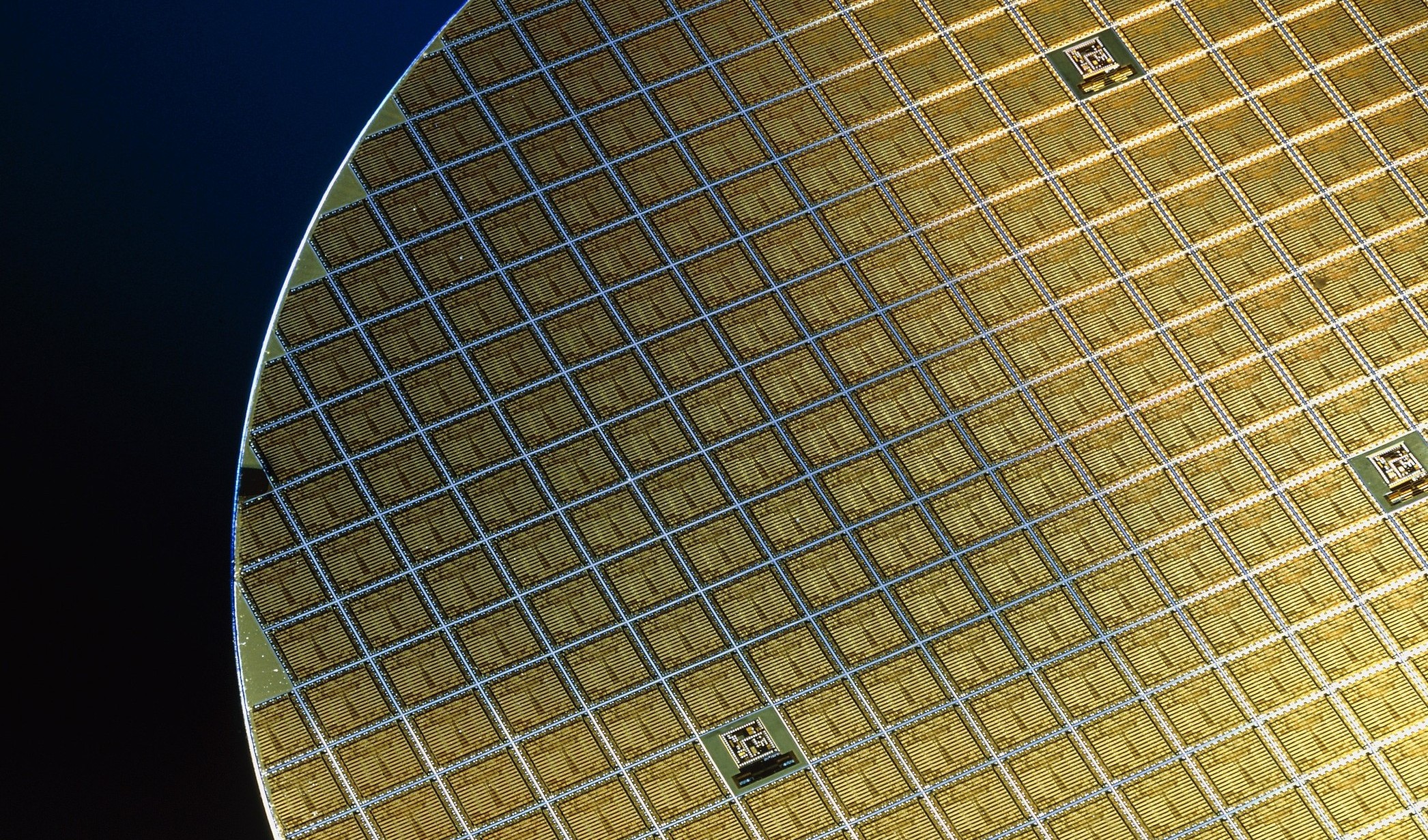

f the gas distribution is uneven, it will lead to inconsistent etching rates across different regions of the wafer, thereby affecting the precision and integrity of the circuit patterns on the chip. For example, when etching minute transistor structures, excessively fast or slow local etching rates may result in transistor dimensions that do not meet the design requirements, ultimately impacting the chip's performance and functionality.

Precise Control of Reactive Gas Flow

Principle of operation: The Shower Head is connected to the gas delivery system, allowing for precise regulation and control of the flow rates of different reactive gases according to the specific requirements of the etching process. Through built-in flow regulation devices, fine adjustments to the flow rate of each gas can be achieved.

Importance: Different etching steps require specific ratios and flow rates of reactive gases to achieve the desired etching effect.

Precise control of gas flow helps maintain a stable chemical reaction process during etching, ensuring that key parameters such as etching selectivity and rate meet process specifications. For example, in selective etching processes for silicon dioxide (SiO₂) and silicon (Si) layers, accurate control of the flow rates of reactive gases such as fluorine-based gases is essential to ensure that the SiO₂ layer is etched away while minimizing etching of the underlying Si layer.

Promoting Sufficient Contact Between Reactive Gases and the Wafer Surface

Principle of operation: Its special showerhead-like structure enables gases to be sprayed out in a dispersed manner, allowing for better coverage of all corners and microstructural areas on the wafer surface, thereby increasing the opportunities for reactive gases to come into contact with the materials to be etched on the wafer surface.

Importance: Sufficient contact between gases and the wafer surface is a prerequisite for ensuring efficient and uniform etching reactions. Only when reactive gases can fully contact every part of the wafer surface that requires etching can the consistency of etching quality across the entire wafer surface be guaranteed, avoiding situations of incomplete or excessive etching in local areas. This is crucial for manufacturing high-quality, high-performance semiconductor chips.

In semiconductor etching, the Shower Head ensures precise, stable, and efficient etching processes through functions such as uniform gas distribution, precise flow control, and promotion of sufficient gas-wafer surface contact, thereby laying the foundation for producing semiconductor chips that meet requirements.

AMTD provides high-precision Showerhead services for core components. Its product lineup primarily encompasses core semiconductor equipment parts, including Shower heads, Face plates, Blocker Plates, Top Plates, Shields, Liners, pumping rings, and Edge Rings. These products are extensively applied in the semiconductor and display panel industries, renowned for their outstanding performance and high market acceptance.