In the intricate process of semiconductor manufacturing, the production of Showerheads stands as the "invisible battlefield" of precision machining technologies. As the core component of the gas distribution system, the microhole arrays on Showerheads serve as precise "gas conduits," whose machining accuracy directly influences the uniformity of thin-film deposition on wafer surfaces. This uniformity, in turn, is closely tied to chip yield and performance. Even minor deviations can lead to chip defects, reducing yield and degrading performance, thereby impacting the market competitiveness of the entire semiconductor product. Thus, while the Showerhead manufacturing process may not be widely recognized, it occupies a pivotal position within the semiconductor manufacturing supply chain.

Technical Challenges: The "Three Highs" Dilemma in Microhole Machining

The microhole machining of Showerheads faces a formidable "three highs" challenge, each imposing stringent requirements on machining technologies:

· High Hardness: Some premium Showerheads are crafted from materials like silicon carbide, which boasts a Mohs hardness of 9.5, approaching that of diamond.

Such extreme hardness causes traditional machining tools to wear rapidly during processing, compromising machining accuracy, increasing costs, and necessitating frequent tool replacements.

· High Density: Take, for instance, a Showerhead corresponding to a 12-inch wafer, which features over 100,000 microholes. This high-density arrangement demands exceptional positioning accuracy and repeatability from the machining equipment to ensure each microhole is precisely machined and adheres to design specifications.

· High Precision: Hole diameter consistency must be controlled within ±0.5μm. In the microscopic realm, achieving such precision is akin to carving intricate patterns onto a needlepoint. Any minor deviation can lead to uneven gas distribution, thereby affecting the quality of thin-film deposition. Traditional techniques like mechanical drilling are prone to hole wall adhesion due to tool vibration and wear, enlarging and distorting hole shapes. EDM (Electrical Discharge Machining), on the other hand, generates a heat-affected zone, altering material properties and expanding hole diameter deviations, both failing to meet high-precision machining demands.

Solutions: Innovative Pathways through Multi-Technology Integration – Breakthroughs by AMTD

Innovations in precision machining technologies offer viable solutions to overcome the "three highs" challenge in Showerhead microhole machining. AMTD, a leader in domestic semiconductor precision machining, has actively explored innovative pathways through multi-technology integration, achieving remarkable results.

Laser-Chemical Composite Machining Technology

AMTD's laser-chemical composite machining technology ingeniously combines the advantages of laser and chemical machining. Initially, a high-energy-density laser beam, particularly a femtosecond laser with its ultra-short pulse width and instantaneous energy release, rapidly cuts and shapes the Showerhead material, forming microhole arrays without generating a heat-affected zone. Compared to traditional laser machining, femtosecond laser-machined microholes exhibit smoother edges and higher diameter accuracy.

Showerhead Manufacturing: The "Invisible Battlefield" of Precision Machining Technologies

In the intricate process of semiconductor manufacturing, the production of Showerheads stands as the "invisible battlefield" of precision machining technologies. As the core component of the gas distribution system, the microhole arrays on Showerheads serve as precise "gas conduits," whose machining accuracy directly influences the uniformity of thin-film deposition on wafer surfaces. This uniformity, in turn, is closely tied to chip yield and performance. Even minor deviations can lead to chip defects, reducing yield and degrading performance, thereby impacting the market competitiveness of the entire semiconductor product. Thus, while the Showerhead manufacturing process may not be widely recognized, it occupies a pivotal position within the semiconductor manufacturing supply chain.

Technical Challenges: The "Three Highs" Dilemma in Microhole Machining

The microhole machining of Showerheads faces a formidable "three highs" challenge, each imposing stringent requirements on machining technologies:

· High Hardness: Some premium Showerheads are crafted from materials like silicon carbide, which boasts a Mohs hardness of 9.5, approaching that of diamond.

Such extreme hardness causes traditional machining tools to wear rapidly during processing, compromising machining accuracy, increasing costs, and necessitating frequent tool replacements.

· High Density: Take, for instance, a Showerhead corresponding to a 12-inch wafer, which features over 100,000 microholes. This high-density arrangement demands exceptional positioning accuracy and repeatability from the machining equipment to ensure each microhole is precisely machined and adheres to design specifications.

· High Precision: Hole diameter consistency must be controlled within ±0.5μm. In the microscopic realm, achieving such precision is akin to carving intricate patterns onto a needlepoint. Any minor deviation can lead to uneven gas distribution, thereby affecting the quality of thin-film deposition. Traditional techniques like mechanical drilling are prone to hole wall adhesion due to tool vibration and wear, enlarging and distorting hole shapes. EDM (Electrical Discharge Machining), on the other hand, generates a heat-affected zone, altering material properties and expanding hole diameter deviations, both failing to meet high-precision machining demands.

Solutions: Innovative Pathways through Multi-Technology Integration – Breakthroughs by AMTD

Innovations in precision machining technologies offer viable solutions to overcome the "three highs" challenge in Showerhead microhole machining. AMTD, a leader in domestic semiconductor precision machining, has actively explored innovative pathways through multi-technology integration, achieving remarkable results.

Laser-Chemical Composite Machining Technology

AMTD's laser-chemical composite machining technology ingeniously combines the advantages of laser and chemical machining. Initially, a high-energy-density laser beam, particularly a femtosecond laser with its ultra-short pulse width and instantaneous energy release, rapidly cuts and shapes the Showerhead material, forming microhole arrays without generating a heat-affected zone. Compared to traditional laser machining, femtosecond laser-machined microholes exhibit smoother edges and higher diameter accuracy.

Subsequently, chemical machining methods further process the microholes, removing residues and tiny burrs generated during laser machining while chemically modifying the microhole surfaces to enhance their properties. Through this laser-chemical composite machining technology, AMTD has achieved ultra-high precision, with hole wall perpendicularity reaching 90°±0.2° and surface roughness Ra<0.08μm, significantly improving Showerhead machining quality.

Laser-Ion Beam Composite Machining Technology

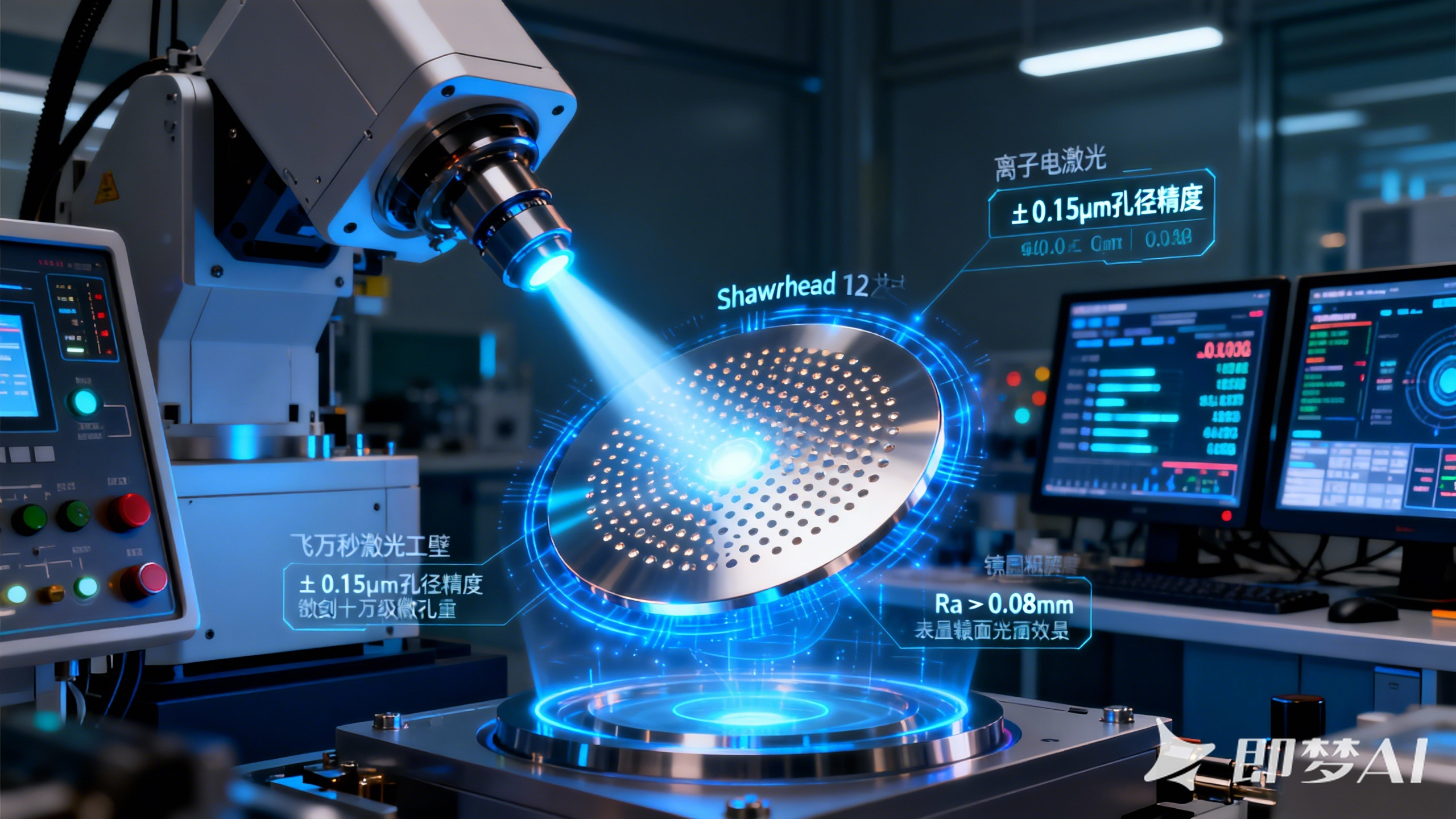

Another innovative technology developed by AMTD is the laser-ion beam composite machining technology. In this approach, laser machining initially shapes the basic form of the microholes, laying the foundation for subsequent fine machining. Laser machining offers rapid processing speeds and high efficiency, enabling the quick formation of numerous microholes on the Showerhead.

Subsequently, an ion beam performs nanoscale corrections on the hole walls.

With its high energy and directionality, the ion beam precisely removes micro-protrusions and defects on the hole wall surfaces, reducing hole diameter deviations to within ±0.15μm. Compared to traditional methods, laser-ion beam composite machining significantly enhances thin-film deposition uniformity. In practical applications, Showerheads processed with this technology have demonstrated substantial improvements in wafer surface thin-film thickness uniformity, increasing chip yield by over 10%.

Intelligent Machining Control System

Beyond advanced machining processes, AMTD also emphasizes the intelligent upgrading of machining equipment. The company has independently developed an intelligent machining control system that integrates high-precision sensors, advanced algorithms, and intelligent control modules. During machining, sensors continuously monitor parameters such as laser power, ion beam energy, and machining speed, feeding data back to the control module.

The control module dynamically adjusts machining parameters based on preset machining models and real-time data, utilizing advanced algorithms to ensure machining process stability and consistency. For instance, when sensors detect minor fluctuations in laser power, the control module immediately adjusts the laser generator's output to restore it to the set value, ensuring microhole machining accuracy remains unaffected. The application of the intelligent machining control system not only enhances machining efficiency and product quality but also reduces technical requirements for operators, providing robust support for large-scale production.

Content Source: Semiconductor Equipment Industry Research Report, Precision Machining Technology Frontier