I. Alignment between Core Advantages of ALD Technology and Performance Requirements of Showerhead

Atomic Layer Deposition (ALD), a thin-film deposition technology based on self-limiting surface reactions, exhibits unique advantages that are highly compatible with the key performance requirements of Showerheads (gas distribution devices) in semiconductor manufacturing:

1. Atomic-Level Precision Control

ALD achieves layer-by-layer deposition by alternately introducing precursor gases, enabling precise control over single-layer thickness (0.1-0.3 nm) and ensuring coating uniformity (within ±1%). This characteristic is crucial for coating the inner walls of the microholes (5-50 μm in diameter) in Showerheads, avoiding the uneven coating caused by shadowing effects in traditional Chemical Vapor Deposition (CVD) processes.

2. Exceptional Step Coverage

ALD can achieve 100% step coverage in complex three-dimensional structures (such as the spiral channels and deep holes in Showerheads), whereas Physical Vapor Deposition (PVD) typically achieves less than 70% coverage. Research by Tokyo Electron (TEL) shows that ALD coatings result in a coating thickness deviation of less than 5% between the corners and planar areas of Showerhead channels.

3. Low-Temperature Process Compatibility

ALD enables deposition at temperatures ranging from 100-300°C, significantly lower than the 400-600°C required for traditional CVD, preventing thermal stress-induced deformation of stainless steel substrates. Applied Materials' ALD process has reduced the deformation of Showerhead substrates from 15 μm to 3 μm.

II. Four Key Application Scenarios of ALD in Showerhead Manufacturing

1. Corrosion-Resistant Coatings

· Material Selection: Dense ceramic materials such as aluminum oxide (Al₂O₃) and silicon nitride (Si₃N₄)

· Typical Case:

In 3D NAND manufacturing, Showerheads are exposed to chlorine-containing etching gases (Cl₂, BCl₃) for extended periods. Lam Research utilized ALD to deposit a 100 nm Al₂O₃ coating, reducing the corrosion rate from 0.5 nm/h to 0.02 nm/h and extending the service life to

over 2000 hours.

2. Contamination-Resistant Coatings

· Surface Functionalization: ALD is used to deposit fluorides (e.g., AlF₃) or hydrophobic polymers to reduce surface energy.

· Effect Validation:

Applied Materials' ALD-AlF₃ coating increased the contact angle of Showerhead surfaces from 65° to 120°, reducing particle shedding by 80% and improving wafer yield by 1.2% in logic chip manufacturing.

3. Microhole Size Control

· Process Innovation:

Initial hole diameters are prepared using Electrical Discharge Machining (EDM), followed by ALD deposition of SiO₂ for size adjustment. Each 100-cycle deposition (approximately 10 nm) reduces the hole diameter by 0.2 μm, achieving nanoscale precision control.

· Application Example:

In EUV photolithography mask manufacturing, Tokyo Electron employed this technology to reduce the coefficient of variation (CV) of Showerhead nozzle diameters from ±3% to ±0.5%, significantly improving photoresist exposure uniformity.

4. Composite Structure Fabrication

· ALD-CVD Hybrid Process:

A 50 nm Y₂O₃ adhesion layer is first deposited using ALD, followed by a thick SiC structural layer using CVD, addressing the issue of coating delamination during direct CVD deposition.

· Performance Improvement:

This process extended the ion bombardment resistance life of Showerheads in Atomic Layer Etching (ALE) equipment from 500 hours to 2000 hours.

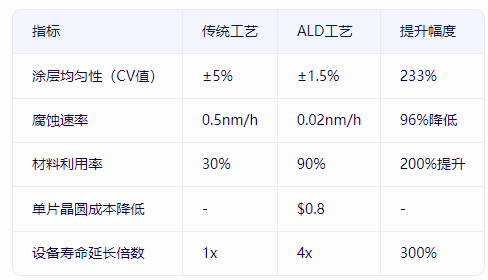

III. Industry Application Data and Economic Analysis

Economic Model:

Take the 12-inch Showerhead as an example. Although the ALD process increases the coating cost by 150 units per piece, it extends the service life (from 500 hours to 2000 hours) and reduces wafer defects (yield rate increased by 1.2-0.8). Based on a monthly production of 50,000 wafers, the annual cost savings can reach $4.8 million.

IV. Technology Development Trends and Challenges

1. Development of Novel Materials

Novel ALD precursors, such as two-dimensional materials (e.g., h-BN) and metal-organic frameworks (MOFs), are under development, aiming to further enhance the high-temperature resistance (>600°C) and chemical stability of Showerheads.

2. Large-Area Uniform Deposition

Current ALD equipment has a deposition rate of approximately 50-100 nm/min, which is insufficient for large-scale production. Spatial ALD technology, which employs parallel of multiple precursors, can increase the rate to 1 μm/min and is currently undergoing industrial validation.

3. Cost Optimization Pathways

Through precursor recovery systems (recovery rate >95%) and process parameter optimization (e.g., shortening purge times), the cost of ALD coatings can be reduced from 500/m2to200/m², approaching the level of traditional PVD processes.

AMTD provides high-precision Showerhead services for core components, with products including Shower heads, Face plates, Blocker Plates, Top Plates, Shields, Liners, pumping rings, Edge Rings, and other core semiconductor equipment parts. These products are widely used in the semiconductor and display panel industries, offering exceptional performance and high market recognition.

Content Sources:

1. Applied Materials Technical Report: "ALD Coatings for Advanced Semiconductor Equipment" (2023)

2. Lam Research White Paper: "Precision Gas Distribution in 3D NAND Manufacturing" (2022)

3. Tokyo Electron R&D Publication: "Hybrid ALD-CVD Process for EUV Applications" (2021)

4. SEMICON West 2023 Conference Proceedings: "ALD Technology Roadmap for 2025+"

5. Journal of Vacuum Science & Technology A, Vol. 41, Issue 3 (2023): "Atomic Layer Deposition for Corrosion Resistance in Semiconductor Tools"