Showerhead, also known in Chinese as "pēn lín tóu" (spray head), "qì tǐ fēnpèi pán" (gas distribution plate), or "yún qì pán" (uniform gas plate), is widely used in semiconductor manufacturing processes such as Physical Vapor Deposition (PVD), Chemical Vapor Deposition (CVD), and etching. It is a critical component in the distribution of various gases. Its primary function is to uniformly distribute gases into the reaction chamber, ensuring that semiconductor materials come into uniform contact with the gases during the reaction process, thereby enhancing production efficiency and product quality.

The Showerhead product features high precision, high cleanliness, and multi-layered/composite surface treatments (such as integration of sandblasting, anodizing, nickel brush plating, and electrochemical polishing, among others). Positioned within the reaction chamber, the uniform gas plate (Showerhead) provides a uniformly deposited gas film layer for the wafer reaction environment, making it a core component in wafer production.

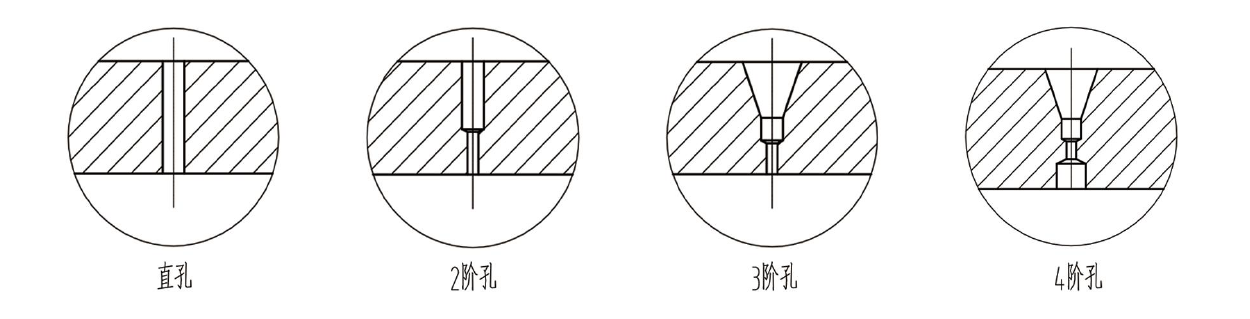

During the wafer reaction process, the surface of the Showerhead is densely covered with micro-holes (ranging from 0.2 to 6 mm in diameter). Through a precisely designed hole structure and gas pathway, specialty process gases must pass through tens of thousands of tiny holes on the uniform gas plate before being uniformly deposited onto the wafer surface. It is crucial to ensure high uniformity and consistency of the film layer across different regions of the wafer. Therefore, in addition to stringent requirements for cleanliness and corrosion resistance, the uniform gas plate also imposes rigorous standards on the consistency of hole diameters and the presence of burrs on the inner walls of the holes. If the tolerance and standard deviation of hole diameter sizes are too large or if there are any burrs on the inner walls, it will result in uneven thickness of the deposited film layer, directly impacting the process yield of the equipment.

In plasma-assisted processes (such as PECVD and dry etching), the Showerhead, as part of the electrode, generates a uniform electric field through radio frequency (RF) power supply to facilitate the uniform distribution of plasma, thereby enhancing the uniformity of etching or deposition.

Four types of micro-hole machining methods for the Showerhead

Features: The micro-hole diameter range of the spray head is generally between 0.2 and 6 (mm), with a tolerance controlled within ±0.01 (mm), and the positional tolerance is ≤0.03 (mm). The uniformity of the micro-holes is within 3σ ≤ 3 μm; the surface roughness of the hole wall is required to be Ra ≤ 0.4 μm. The limit ratio of hole depth to hole diameter reaches approximately 50 times the diameter.

Materials of Showerhead

Based on different materials, Showerheads can be classified into silicon-based Showerheads (also known as silicon electrodes), metal Showerheads (made of aluminum alloy, stainless steel, pure nickel, etc.), and other types (such as CVD-SiC Showerheads). Aluminum metal is commonly used due to its high thermal conductivity and corrosion resistance. Quartz or ceramic can also be used to manufacture shower heads.

TAPE A 200 Aluminum Alloy/Stainless Steel: Primarily used for machining Showerheads with larger hole diameters (2-6 mm), requiring small machining centers with spindle speeds up to 18,000 RPM or 30,000 RPM, and employing motorized spindles to ensure machining accuracy.

Silicon Carbide (CVD-SiC): Suitable for high-demand applications such as etching equipment. Domestically produced silicon carbide Showerheads are priced at approximately 150,000 yuan, but their machining accuracy is limited, and they still rely on imported products.

Monocrystalline Silicon/Quartz Glass: Brittle materials that require specialized ultrasonic drilling and tapping machines. Ultrasonic vibration is used to reduce cutting temperatures and facilitate chip removal, preventing fractures.

High-Purity Ceramics (Alumina, Silicon Nitride): Commonly used in high-temperature and high-pressure environments due to their stability and corrosion resistance, accounting for 79% of the global market share.

Silicon-Based Showerheads: The mainstream choice (accounting for 79% of the market), priced at approximately 80,000 to 90,000 yuan, with their lifespan affected by plasma corrosion, necessitating regular replacement.

Manufacturing of MOCVD Reaction Chamber Showerheads

MOCVD reaction chamber showerheads are typically manufactured using high-purity ceramic materials such as alumina and silicon nitride. Ceramic materials exhibit excellent high-temperature stability and corrosion resistance, enabling stable operation under high-temperature and high-pressure conditions while minimizing contamination of reactive gases. The main manufacturing processes for MOCVD reaction chamber showerheads include the following aspects:

1.Material Selection: Based on the characteristics of the reactive gases and operating conditions, suitable high-purity ceramic materials such as alumina and silicon nitride are chosen.

2.Structural Design: The geometric shape and position of the showerhead are designed according to the size and shape of the reaction chamber. Optimized design can enhance the uniformity and stability of compounds within the reaction chamber.

3.Machining Process: Selected materials are processed using techniques such as mechanical machining, hot isostatic pressing, and injection molding to manufacture showerheads that meet design requirements.

4.Key Material Considerations: The choice of showerhead material directly influences its performance and service life. Commonly used materials include metals, ceramics, and polymers. Metal materials are typically used for growth under low-temperature conditions, while ceramic materials, with their excellent high-temperature stability and corrosion resistance, are suitable for growth under high-temperature and high-pressure conditions.

5.Surface Treatment: Surface treatment enhances the surface flatness and smoothness of the showerhead, further improving its growth efficiency and material quality. Common surface treatment methods include polishing, sandblasting, and chemical etching.

Tooling System; Utilizing a Thermal Shrink-Fit Holder + Solid PCD Tool

The thermal shrink-fit holder boasts high precision and stable clamping strength, with tool deflection ≤3μ, ensuring high precision during high-speed machining.

The hole structure of the showerhead is crucial for the uniformity of gas deposition in a wafer environment. Therefore, the design of the showerhead directly impacts the yield of wafer production. AMTD leverages advanced technology and mature processes to provide Showerhead and semiconductor precision component products. By adhering to technological innovation, AMTD has established a comprehensive system encompassing Showerhead R&D, surface treatment, micropore machining, welding, and quality control. Its products are widely applied in the semiconductor and display panel industries.

上一篇:The Underlying Trends Behind the Thinning of Wafers

下一篇:A Comprehensive Overview of Key Components in Semiconductor Equipment